小优智能科技有限公司成立于2015年底,是一家专注于高精度3D机器视觉模组研发、生产及销售的高科技企业。

公司自主研发的3D机器视觉模组采用激光/DLP白光编码光栅结构光+双工业相机方案,还原物体三维信息,广泛应用于消费电子领域、工业领域和安防领域,具有精度高、速度快、成本低的优势。

A brief discussion on the application of machine vision

1. The concept of machine vision

Vision is a powerful way of perception for humans. We use vision to quickly and conveniently obtain a lot

of information about the surrounding environment. Giving visual perception to machine systems is machine

vision. With the rapid development of artificial intelligence today, the technology of converting electronic

devices into image signals has also matured. Now, the application of machine vision can be realized by

simply abstracting various target features from image signals through artificial intelligence analysis,

calculation and processing.

2. Application scenarios of machine vision

Industrial inspection applications

In industrial inspection, the outstanding advantages of machine vision, such as non-contact, fast speed,

appropriate accuracy, and strong anti-interference ability on site, have been utilized, making machine

vision technology widely used and achieving huge economic and social benefits.

It has been widely used in plate processing inspection, glass substrate surface inspection, PCB surface

inspection, metal surface visual inspection, diode substrate inspection, printed circuit board defect

inspection, and automatic identification of weld defects.

The use of machine vision in industrial inspection can improve the flexibility and automation of production.

On the one hand, machine vision can be used in some dangerous working environments or occasions

where artificial vision cannot meet the requirements; on the other hand, in large-scale industrial production

processes, machine vision inspection can greatly improve production efficiency and the degree of

intelligence of production.

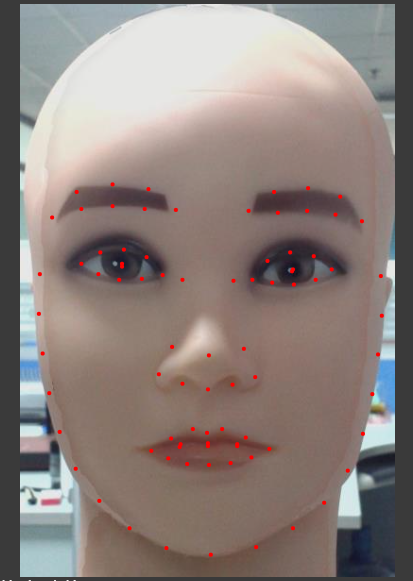

Image recognition

Image recognition, in simple terms, is the use of machine vision to process, analyze and understand

images, and identify a variety of objects and targets. It is very powerful. Currently, the main content to be

identified is various targets such as people and vehicles. In the industrial field, there is often a need to

identify logos with clear information, such as OCR, one-dimensional codes, and two-dimensional codes.

Identifying signs that clearly indicate information can help improve production efficiency and reduce production costs. Most commercial scenarios for image recognition are still in the blue ocean, with potential yet to be developed.

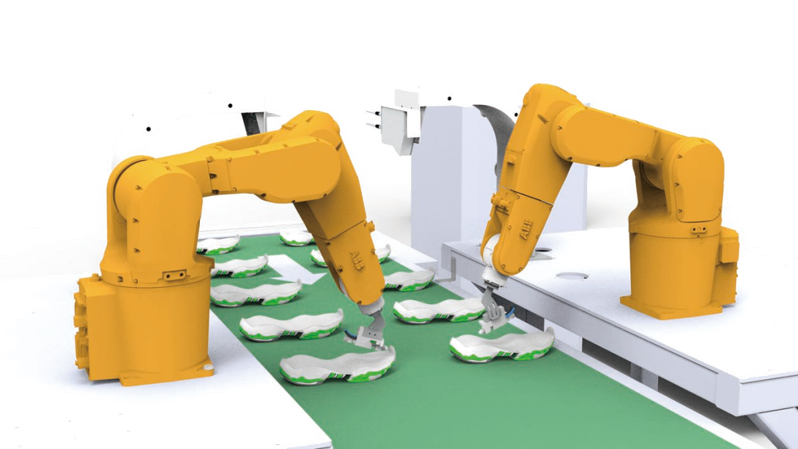

Positioning and measurement

Using machine vision to locate parts or products, this positioning application often assists robots or other

actuators to achieve related actions. Generally speaking, positioning can assist robots to achieve actions

such as painting, gluing, grasping, welding, etc.

The application of machine vision in measurement is mainly used to measure the size of parts and various

products. In addition to using industrial cameras for two-dimensional size measurement, three-dimensional

size measurement can be achieved using technologies such as structured light and 3D TOF. It provides

high-precision monitoring of the basic characteristic dimensions and assembly effects of products.

The application of machine vision in industrial positioning and measurement, on the one hand, reduces

labor costs, and on the other hand, the positioning and measurement of machine vision have

high-precision characteristics, which improves the yield rate of industrial finished products.