小优智能科技有限公司成立于2015年底,是一家专注于高精度3D机器视觉模组研发、生产及销售的高科技企业。

公司自主研发的3D机器视觉模组采用激光/DLP白光编码光栅结构光+双工业相机方案,还原物体三维信息,广泛应用于消费电子领域、工业领域和安防领域,具有精度高、速度快、成本低的优势。

First of all, we need to understand what role the light source plays in machine vision:

1. Illuminate the target to improve brightness;

2. Form imaging effects conducive to image processing, reduce the complexity of the system and the requirements for image processing algorithms;

3. Overcome ambient light interference, ensure image stability, improve the accuracy and efficiency of the system.

Proper light source lighting design can best separate the target information from the background information in the image, which not only greatly reduces the difficulty of image processing algorithm, but also improves the accuracy and reliability of the system. Unfortunately, there is no universal machine vision lighting system to deal with different detection requirements, so for each specific case, it is necessary to design a suitable lighting device to achieve the best results. Inappropriate lighting will cause a lot of problems, machine vision light source is so important, but often ignored by many people.

At present, the machine vision light source mainly uses LED (light-emitting diode), which is widely used in the industry due to its high shape freedom, long service life, fast response, good monochrome, diverse colors, and comprehensive high cost performance characteristics:

1. Shape freedom

An LED light source is composed of many individual leds, so compared with other light sources, it can be made into more shapes, and it is easier to design the shape and size of the light source for the user's situation.

Second, long service life

In order for the image processing unit to obtain accurate and repeatable measurement results, the lighting system must ensure that it can provide stable image input for a long time. LED light source in continuous work after 10,000 to 30,000 hours, brightness attenuation, but far better than other light source effect. In addition, the control system makes it work intermittently, which can inhibit the heating of the light emitting tube, and the service life will be doubled.

Third, the response speed is fast

LED light tube response time is very short, the real meaning of the response time is to ensure that multiple light sources or different areas of a light source can be switched between the work, using a special controller to power the LED light source, the maximum illumination time is less than 10s.

4. Diverse colors

In addition to the shape of the light source, another aspect of getting a stable image input is choosing the color of the light source. Even the same shape of the light source, due to the different color of the image will be very different. In fact, how to use the technical characteristics of light source color to get the best contrast image effect has been the main direction of light source development.

5. Low comprehensive operating costs

Choose cheap products with no guaranteed performance, and the savings of the initial investment will soon be offset by the daily maintenance and repair costs. Other light sources not only consume 2 to 10 times the power of LED light sources, but also need to be replaced almost every month, wasting a lot of valuable time for maintenance engineers. And the more light sources put into use, the greater the cost of device replacement and labor, so the selection of long-life LED light sources is very economical in the long run.

Machine vision lighting technology Basic knowledge:

1) Irradiation method

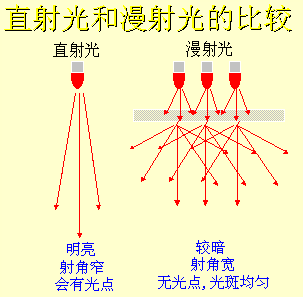

Selecting different light sources, controlling and adjusting the direction of the incident light shining on the object are the most basic parameters of machine vision system design. It depends on the type of light source and relative to the location of the object, there are generally two most basic ways: direct light and diffuse light, and all other ways are extended from these two methods.

Direct light: the incident light basically comes from one direction, the Angle is small, it can project the shadow of the object;

Diffuse light: Incident light comes from many directions, or even all directions, and it does not cast a significant shadow.

2) Reflection mode

There are two different reflection characteristics of light reflected by objects: direct reflection and diffuse reflection.

Direct reflection: The Angle of reflection of light is equal to the Angle of incidence. Direct reflection is sometimes very useful, and sometimes it can produce a very strong glare. Specular reflection should be avoided in most cases.

Diffuse dispersion: The light that strikes an object diffuses in all directions. In most practical cases, diffuse light forms in a range of angles and depends on the Angle of the incident light.

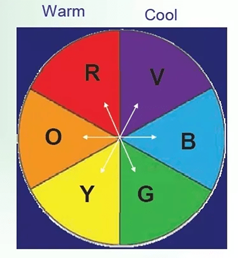

3) Color

A large part of the electromagnetic spectrum is visible to the human eye, and electromagnetic radiation in this wavelength range is called visible light, ranging from 400nm to 760nm (some people can observe 380 to 780nm), that is, from purple 380nm to red 780nm.

A color ring is a sequence of colors in the visible light spectrum, forming red connected to purple at the other end. The color ring used in machine vision typically includes 6 different colors, divided into two broad categories: warm colors and cool colors. Warm colors are made up of red tones and cool colors come from blue tones. Usually illuminated with light at the opposite color temperature, the image can achieve the highest level of contrast; Light exposure of the same color temperature can be effectively filtered out. Therefore, the flexible use of color temperature characteristics is very helpful for us to choose a light source.

4) Bright field and dark field of view

Bright field is the most commonly used lighting scheme, formed by direct light from the front. The dark field is mainly formed by low Angle or backlight illumination. For different project detection needs, choose different types of lighting methods, generally speaking, the dark field will make the background dark, and the object under test is bright.

5) Classification of light sources

At present, there are mainly the following categories:

a) Color

Commonly used light source color is concentrated in the visible light range, mainly white (composite light), red, blue, green, in addition to infrared light is also more popular, and ultraviolet light due to various reasons, fewer applications.

b) Shape

Each manufacturer will be classified according to the shape characteristics of different light sources, which is also the current mainstream classification, such as ring light source, ring low Angle light source, strip light source, dome light source (bowl light source/dome light source), surface light source, etc.

c) Working principle/characteristics

It is classified according to different application methods or principles, mainly shadowless light source, coaxial light source, point light source, line light source, backlight source, combined light source and structural light source.

Common light source types and lighting methods

1. General purpose lighting (direct lighting) : the light is directly directed at the object to get a clear image.

This type of light is useful when we need to get a high contrast image of an object. But when we shine it on a bright or reflective material, it will cause a mirror-like reflection. General lighting generally uses ring or point lighting. Ring light is a commonly used general lighting method, which is easy to install in the lens and can provide sufficient illumination to diffuse reflective surfaces.

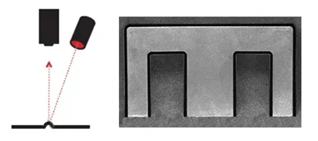

2. Dark field lighting: Dark field lighting is to provide low Angle lighting relative to the object surface.

Using an industrial camera to shoot a mirror, if you can see the light source in the field of view, it is considered to be bright field lighting, and on the contrary, you can not see the light source in the field of view is dark field lighting. Therefore, whether the light source is bright field lighting or dark field lighting is related to the position of the light source. Generally, dark field lighting is applied to the illumination of protruding parts of the surface or the illumination of surface texture changes.

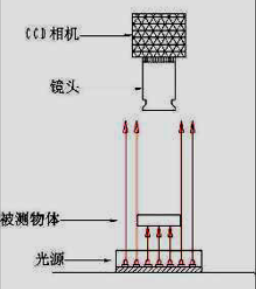

3. Backlight lighting: Light from the back of the object to the uniform field of view, through the camera can see the profile of the object.

Backlighting is often used to measure the size and orientation of objects. Backlighting creates a strong contrast. When backlighting is applied, surface features may be lost. For example, it is possible to measure the diameter of a coin using backlight technology, but it is not possible to determine the front and back of the coin.

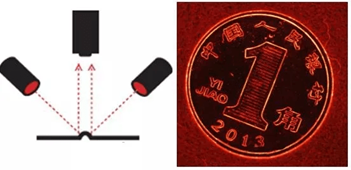

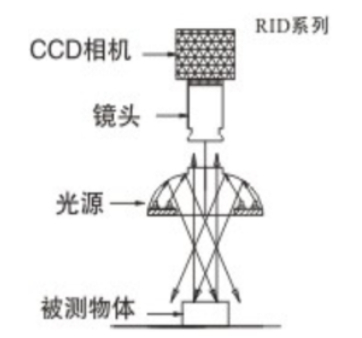

4. Diffuse lighting: Continuous diffuse lighting is applied to the reflectivity of the object surface or the surface has a complex Angle.

Continuous diffuse lighting uses hemispherical uniform lighting to reduce shadow and specular reflection. This lighting method is very useful for lighting fully assembled circuit boards. This light source can achieve uniform illumination in the 170 sphericity solid Angle range.

5. Coaxial lighting: The formation of coaxial light - the astigmatism coming out of the vertical wall is emitted to a splitter that makes the light downward, and the camera looks at the object through the splitter from above.

This type of light source is particularly helpful for detecting highly reflective objects, and is also suitable for detecting objects whose area is not obvious under the influence of shadows in the surrounding environment.

6. Polarizer: Only the light whose vibration direction is parallel to its allowable direction is allowed to pass through, and the vertical component is cut off.

For specific applications, choosing the best lighting system from many schemes is the key to the stable operation of the entire image processing system.