小优智能科技有限公司成立于2015年底,是一家专注于高精度3D机器视觉模组研发、生产及销售的高科技企业。

公司自主研发的3D机器视觉模组采用激光/DLP白光编码光栅结构光+双工业相机方案,还原物体三维信息,广泛应用于消费电子领域、工业领域和安防领域,具有精度高、速度快、成本低的优势。

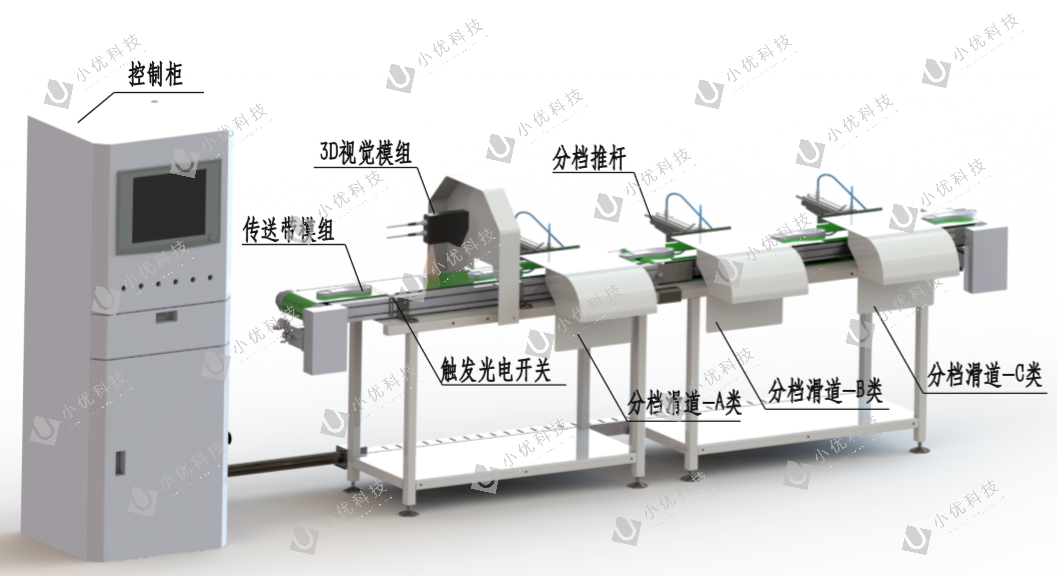

The 3D scanning and intelligent sorting system of the shoe billet production line of XiaoU Technology is mainly used in the intelligent sorting process of the shoe billet production line of the shoe factory, which provides technical support for the factory to save labor cost, improve production efficiency and provide automatic transformation.

The method of 3D scanning and intelligent sorting of assembly line blanks mainly includes line laser 3D vision module scanning, stitching of blanks' contour lines, 3D point cloud model library of blanks, three-dimensional size detection of blanks, and sorting of blanks of different sizes.

The linear laser 3D vision module has been calibrated, and the single-line scanning accuracy is 0.2mm.The number of single-line scanning points can be up to 680 points. This parameter is related to the resolution of gigabit network industrial cameras. High resolution cameras can be selected according to needs.

Displacement of conveyor belt in send the shoes to be detected billet, encoder based on fixed displacement according to the trigger signal, through external trigger signal line laser 3 d camera photograph steady scanning, through the line laser 3 d camera calibration and conveyor system, ensure the line laser 3 d camera scanning each contour line, in the conveyor belt system in the joining together of stability interval and enough precision.

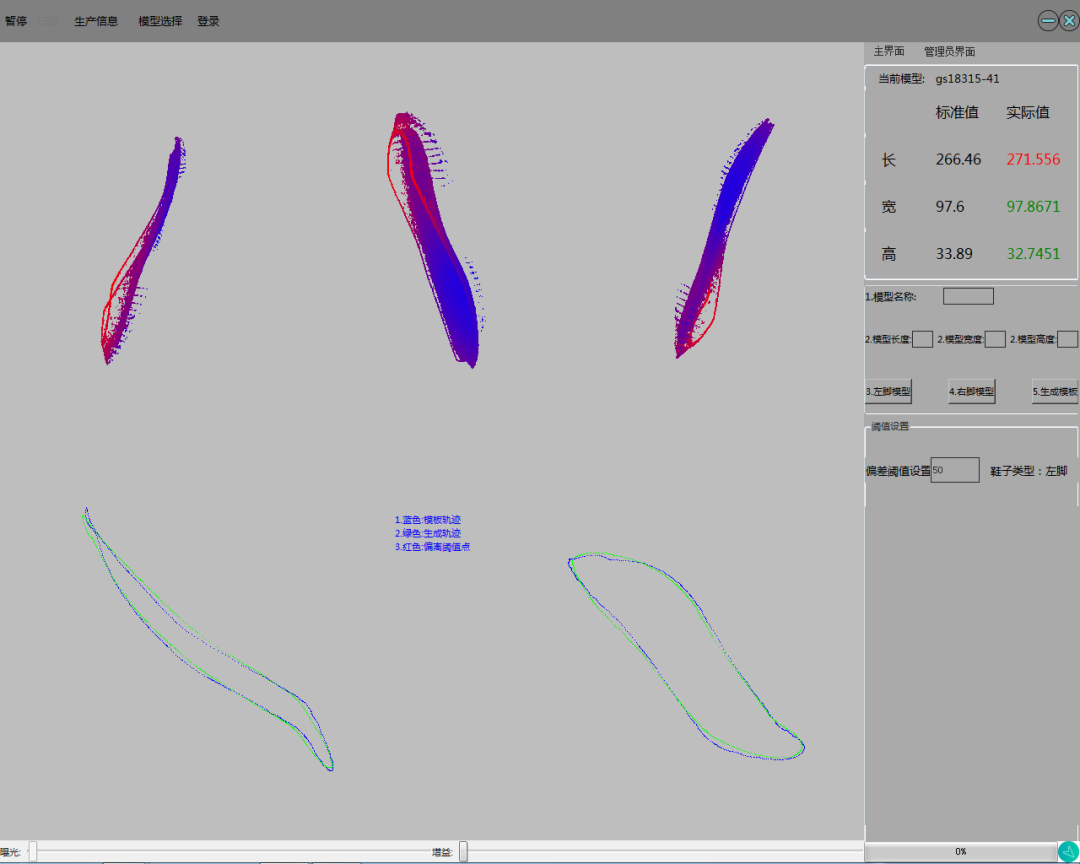

Through the above two areas of coordination work, assembly line of shoes 3 d information is accurately capture, PC receives the laser 3 d grinding module shoes billet three-dimensional point cloud data, and the three-dimensional measurement data, calculated by scan information shoes billet length, width, and through the electromagnetic valve spring thrust unit of length in different sizes within the scope of the billet sorting your shoes.At the same time, the upper computer interface is simple and intuitive, which is convenient for on-site staff to view the automatic detection situation of the assembly line in real time. The upper computer interface is shown in the figure below: