小优智能科技有限公司成立于2015年底,是一家专注于高精度3D机器视觉模组研发、生产及销售的高科技企业。

公司自主研发的3D机器视觉模组采用激光/DLP白光编码光栅结构光+双工业相机方案,还原物体三维信息,广泛应用于消费电子领域、工业领域和安防领域,具有精度高、速度快、成本低的优势。

Light source is an important factor affecting the input of machine vision system, because it directly affects the quality of input data and at least 30% of the application effect.Since there is no universal machine vision lighting device, the lighting device to be affected is selected for each specific application.Many industrial machine vision systems use visible light as a source of light, mainly because it is readily available, inexpensive, and easy to use.Several common visible light sources are incandescent lamps and fluorescent lamps.But one of the biggest drawbacks of these sources is that the light energy is not stable.Take fluorescent lamp for example, in the first 100 hours of use, the light energy drops 15%, as the use of time increases, the light energy will continue to decline.Therefore, how to keep the light energy stable to a certain extent is an urgent problem to be solved in the practical process.On the other hand, the ambient light will change the total light energy of these light sources on the object, so that the output data has noise. The method of adding protective cover is generally adopted to reduce the influence of ambient light.Due to the above problems, in today's industrial applications, for some demanding detection tasks, X-ray, ultrasonic and other invisible light is often used as the light source.But in general applications, LED machine vision light source gradually become the leading role.

LED light source has the following characteristics: 1, long service life, 10,000 to 30,000 hours or so.2, LED light source is composed of many LED particles arranged, can be composed of different shapes of different angles of the light source.3, LED particles have different colors and different wavelengths. Users can choose light sources of different wavelengths according to the characteristics of the detection object to highlight the detection characteristics so as to achieve the ideal effect.4. Good stability.Compared with other light sources, the stability of LED light source is greatly enhanced, which is more conducive to providing quality images for the system.

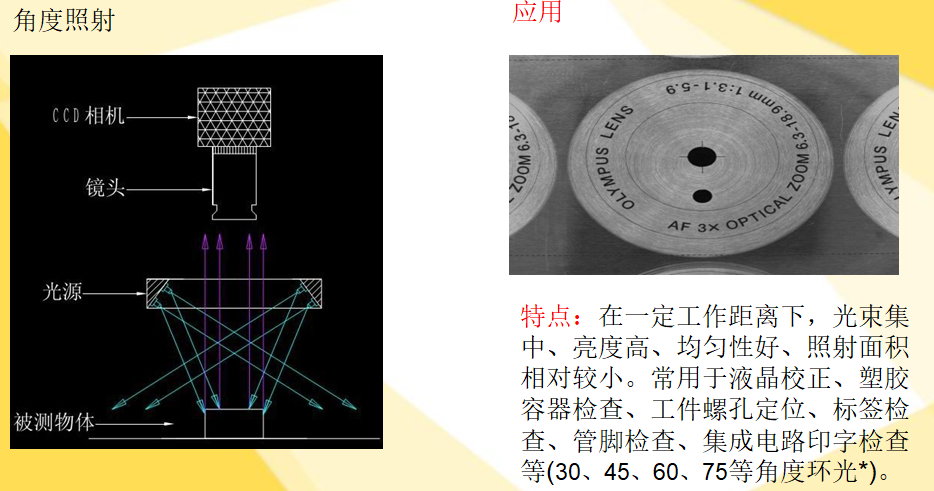

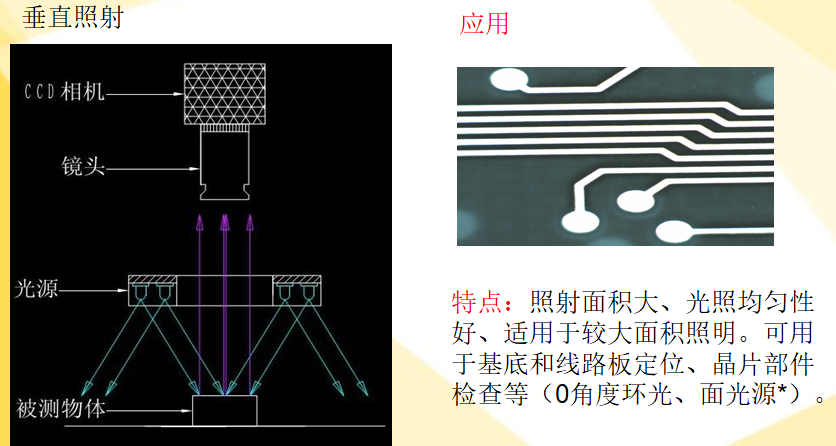

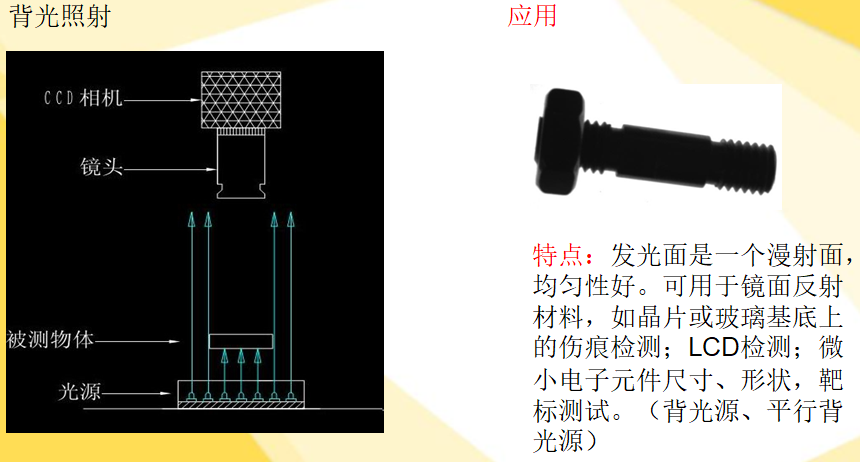

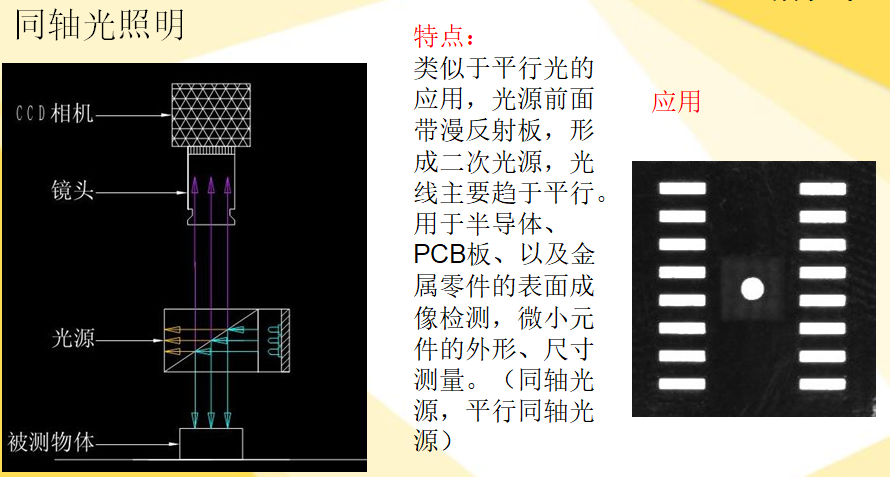

The illumination system constituted by the light source can be divided into back illumination, forward illumination, structural light and frequency flash illumination.Among them, backlighting is between the light source and the camera, its advantage is to get a high contrast image, LED surface light and parallel light is used in this way, to highlight the outline of the product, such as the workpiece size measurement is used in this method.Forward lighting means that the light source and the camera are located on the same side of the measured object, which is easy to install. For example, strip light source, coaxial light source, circular light source, dome light source and line light source are all used in this way, which is the most commonly used lighting method.Structured light illumination is to project gratings or linear light sources onto the measured object, and demodulate the three-dimensional information of the measured object according to the distortion generated by them, which is relatively rare.Frequency flash lighting is a high frequency pulses of light irradiation to the object, requirement of the scanning speed of the camera and light source stroboscopic synchronous speed, the stroboscopic illumination method generally used light source controller to control the function of the light source to stroboscopic, stroboscopic works can greatly increase the brightness of the light source and life, almost all the LED light source can be use strobe lighting.

Regardless of the lighting method, there is only one purpose: to improve the life of the light source and provide a stable, high-contrast image for the image acquisition mechanism.

White light sources are usually defined by the color temperature, and colors with a high color temperature tend to be blue (cool colors, color temperature >;5000K), colors with a low color temperature tend to be red (warm colors, color temperature <3300K), the boundary between 3300 and 5000K is called intermediate color. White light source has wide applicability and high brightness, especially when shooting color images.

Blue light source is between 430-480, suitable for products: silver background products (such as sheet metal, machining parts, etc.), metal printing on the film.

The wavelength of the red light source is usually between 600-720, its wavelength is longer, can pass through some dark objects, such as the bottom material black transparent soft plate hole location, green circuit board detection, transmission film thickness detection, the use of red light source can improve the contrast.

The wavelength of green light source is 510-530, between red and blue, mainly for products: red background products, silver background products (such as sheet metal, machining parts, etc.).

The wavelength of infrared light is generally 780-1400, and infrared light belongs to invisible light with strong transmittance.General LCD screen detection, video monitoring industry is widely used.

The wavelength of ultraviolet light is generally 190-400. Our company mainly uses ultraviolet light of 385 wavelength, which has short wavelength and strong penetration. It is mainly used in document detection, touch screen ITO detection, fabric surface damage detection, glue overflow detection, metal surface scratch detection and so on.