小优智能科技有限公司成立于2015年底,是一家专注于高精度3D机器视觉模组研发、生产及销售的高科技企业。

公司自主研发的3D机器视觉模组采用激光/DLP白光编码光栅结构光+双工业相机方案,还原物体三维信息,广泛应用于消费电子领域、工业领域和安防领域,具有精度高、速度快、成本低的优势。

Project background:

Automobile bumper inspection of a certain enterprise: Manual inspection of bumpers for surface defects.

However, workers are prone to fatigue and boredom when faced with high-intensity, repetitive labor,

which leads to low work efficiency and missed inspections. Intelligent and automated transformation and

upgrading are effective ways to solve this problem.

Workflow:

Workers lift the bumper with the front facing up onto the tooling on the assembly line, and the bumper is

perpendicular to the movement direction of the assembly line. When the product arrives at the

predetermined inspection station, the 3D camera takes a photo of the bumper and sends a 2D photo point to guide the robot to the position, and then the 2D camera takes a photo of the product for defect detection.

Project requirements:

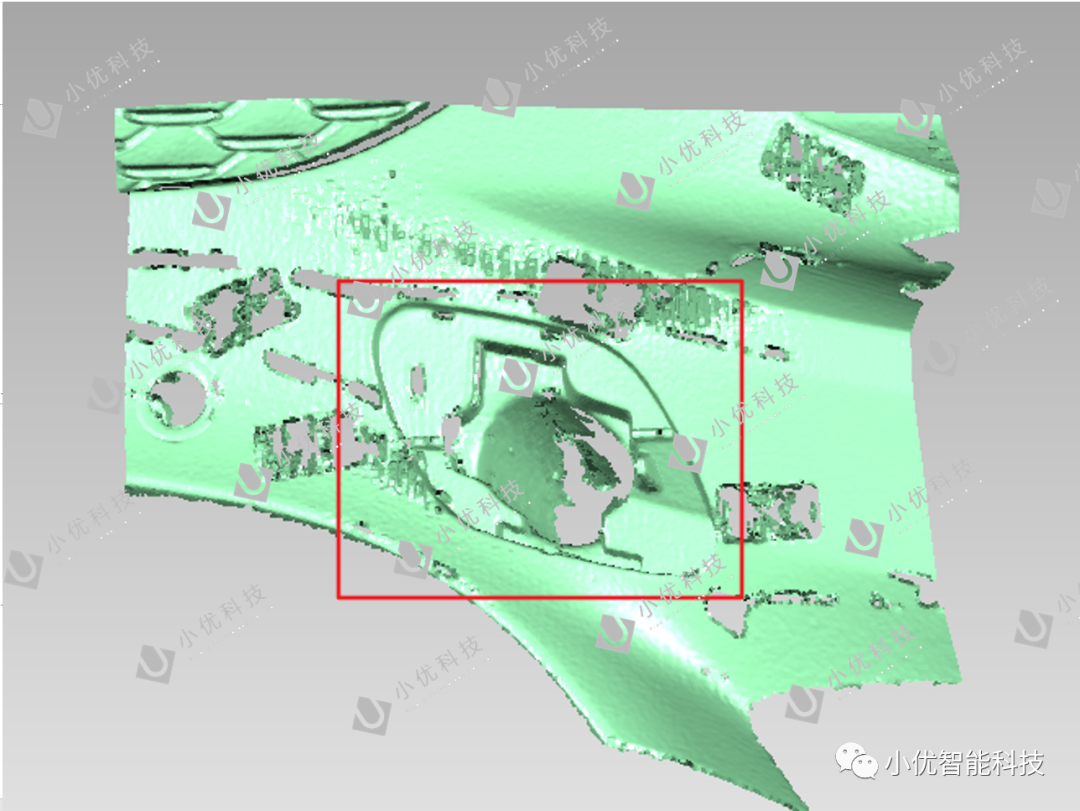

3D vision selects the trailer cover position on the bumper as shown in Figure 1 below (the red frame in

Figure 2), or other coordinates of two features to the robot (these two points are used as reference points).

3D vision calculates the correct position of the robot based on the position changes of the two references.

The robot follows the trajectory of the sent points to ensure that the position deviation of each vision is

within ±0.5mm.

Figure 1

Figure 2

Technical analysis:

1. The product needs to be positioned before taking a photo, but the product size is too large, so a 3D

camera can be used to solve this problem;

2. The binocular structured light 3D camera is selected to meet the field of view and accuracy requirements;

3. Three-dimensional vision + two-dimensional visual recognition technology makes the detection system

more intelligent.

Customer benefits:

1. Reduce the rate of manual missed detection;

2. Improve work and detection efficiency;

3. Improve the stability of detection results.

4. Reduce labor costs.