小优智能科技有限公司成立于2015年底,是一家专注于高精度3D机器视觉模组研发、生产及销售的高科技企业。

公司自主研发的3D机器视觉模组采用激光/DLP白光编码光栅结构光+双工业相机方案,还原物体三维信息,广泛应用于消费电子领域、工业领域和安防领域,具有精度高、速度快、成本低的优势。

Cured Tire Sidewall Scanning Machine 2.0

This device can automatically recognize and identify the letters,numbers,patterns,and custom logos on the tire sidewall.

Device Function:

Extra wrong character detection, Missing Character Recognition, Pattern Logo Recognition, Standard Comparison, Alarm Position Display, Standard Tire Generation Template And Other Function

Features:

Adopt Neural Networks technology to quickly identify characters and patterns based on their features, with high recognition accuracy;

Easy to operate and automatically recognize tire models and adjust the Shooting position;

No manual required, double-side scanning at the same time;

The algorithm is robust and new tire specifications do not require relearning

The testing standards can be obtained through MES (online and offline), local database, standard tire generation template, etc.;

This system uses a self-developed visual inspection platform to achieve customized function development.

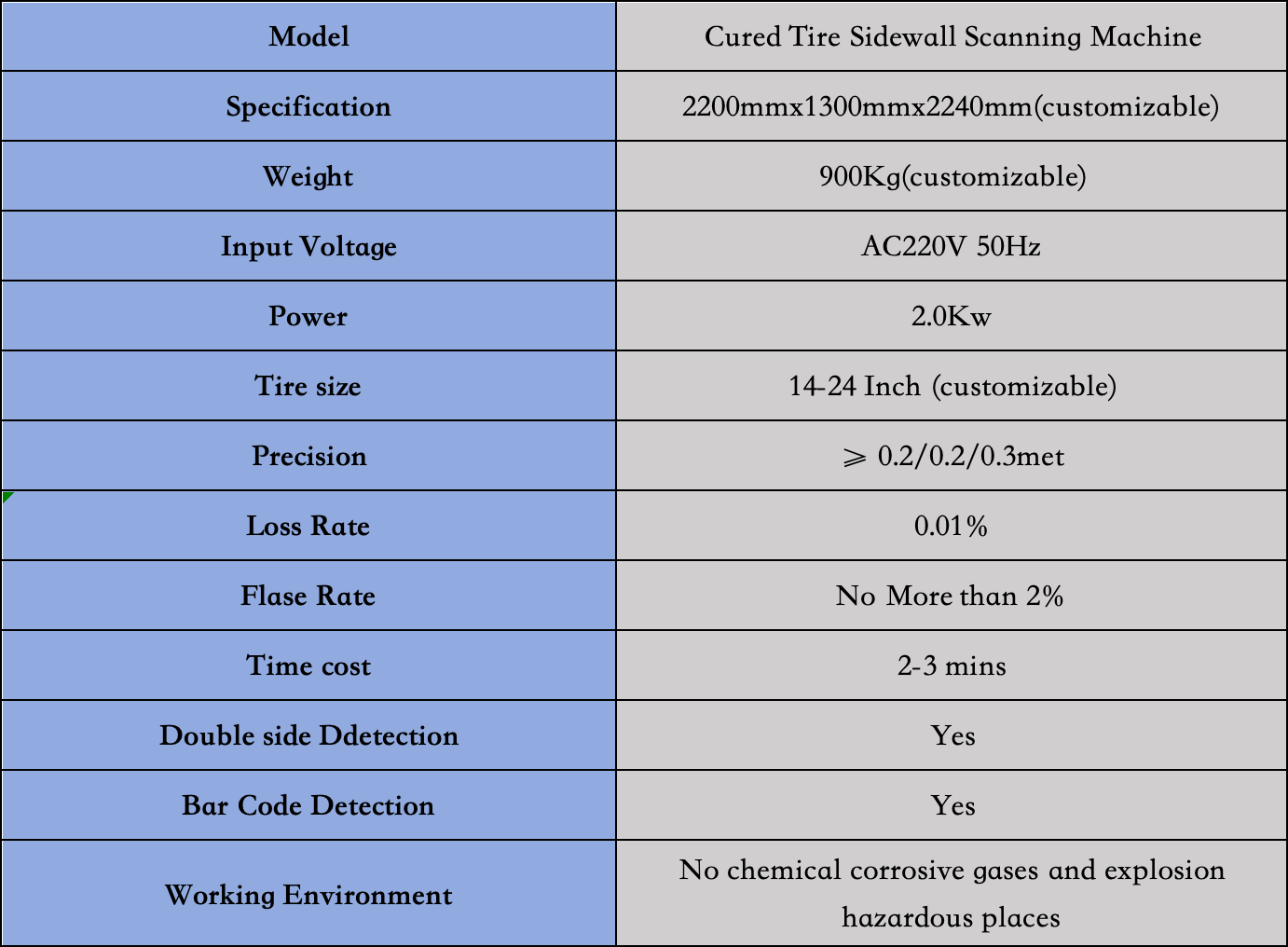

Specification Parameter

Product Value

. A Single person is capable of completing all operations, eliminating the traditional work mode that requirecollaboration between the quality department and multiple factory personnel for changes;

It can achieve seamless integration with the MES system and realize on/off control of the vulcanizing machine;

By increasing the detection rate and reducing the occurrence rate, the RPN value was reduced to meets theaudit reguirements of the host factory;

Improve detection efficiengy. Manual inspection takes about 20 minutes, while this equipment only takes about 2-3 minutes;

Reduce waiting time for vulcanizing machines, save energy and reduce consumption;

Effectively avoid batch quality incidents caused by human inspection errors, thus reducing the market risk for the companylowering quality costs and enhancing the company's brand image;

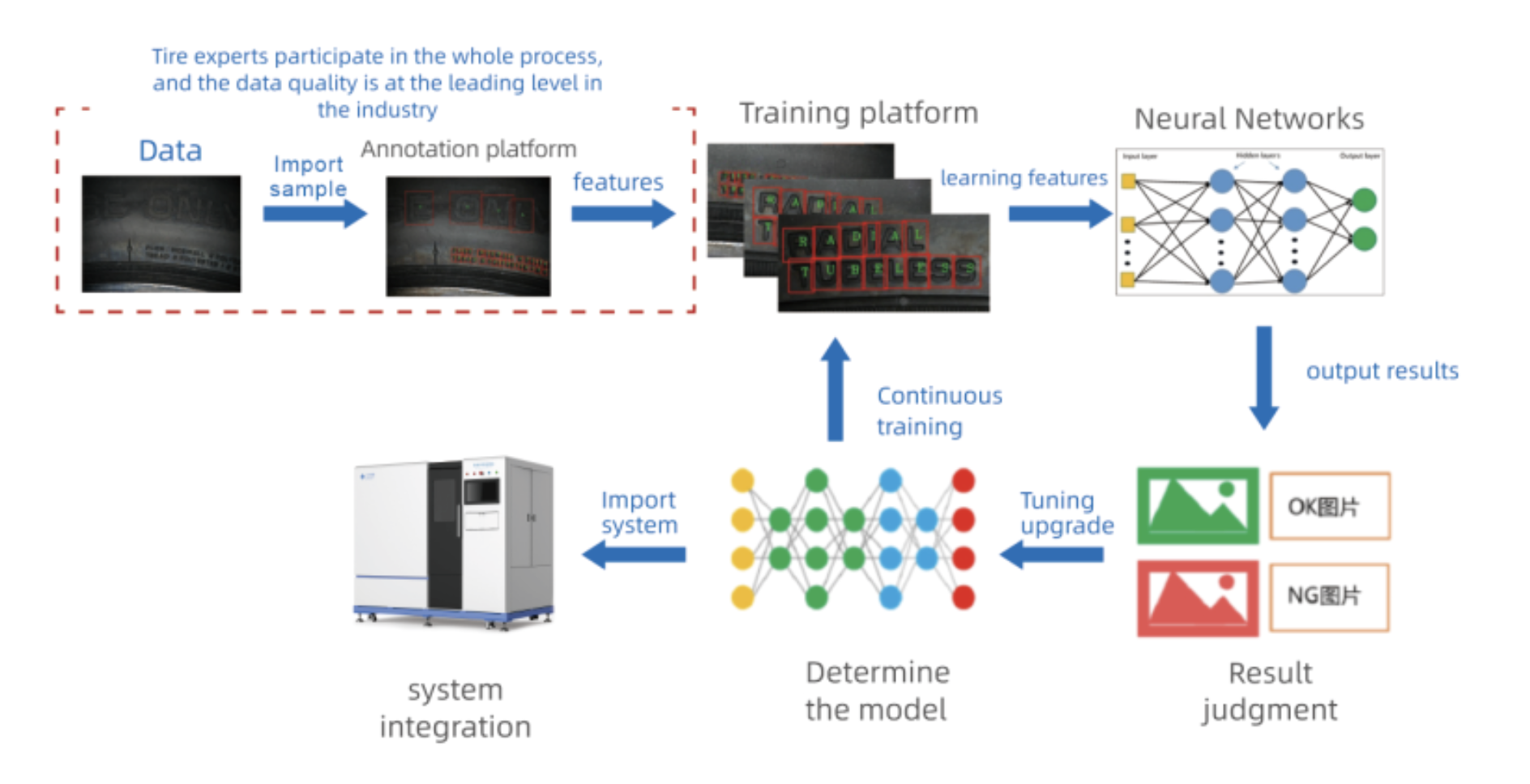

Working Procedure

Application Video: