小优智能科技有限公司成立于2015年底,是一家专注于高精度3D机器视觉模组研发、生产及销售的高科技企业。

公司自主研发的3D机器视觉模组采用激光/DLP白光编码光栅结构光+双工业相机方案,还原物体三维信息,广泛应用于消费电子领域、工业领域和安防领域,具有精度高、速度快、成本低的优势。

Project background:

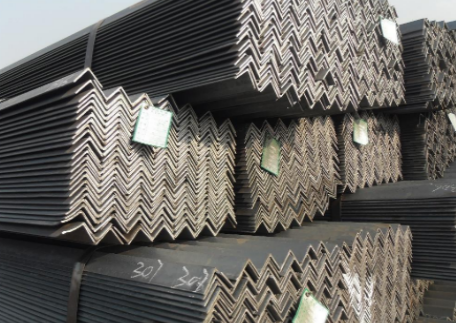

The process of hanging signs is called steel marking. At present, enterprises mainly use manual positioning

and welding. However, with the acceleration of production pace, marking personnel are prone to fatigue

and boredom when facing high-intensity and repetitive labor, which leads to low work efficiency and wrong

marking positions. At the same time, harsh environments such as high dust and high noise will also cause

harm to practitioners. These problems faced by manual operations also restrict the further development of

enterprises, and intelligent and automated transformation and upgrading are effective ways to solve this

problem.

Project requirements:

3D vision identifies one of the most protruding angles in the center of the angle steel stack and sends the

non-edge position of the angle steel to the robot, which then welds the studs and labels to the angle steel.

Technical analysis:

1. Traditional 2D vision cannot obtain the position information of the protrusion, and the 3D camera can

meet the requirements.

2. Use DLP binocular structured light 3D camera, the camera is installed on the robot and the distancecan be adjusted appropriately according to the on-site situation.

Customer benefits:

1. Improve production efficiency.

2. Reduce labor costs.

3. Enjoy perfect after-sales service and technical support.